Amazon recently launched its Vulcan robot, which incorporates advanced tactile technology, allowing it to manipulate items as flexibly as a human. This innovation is set to disrupt the traditional design concepts of industrial robots Avoid contact, ushering in a revolutionary change for the automated warehousing industry.

At the Delivering the Future seminar in Dortmund, Germany, Amazon announced that the Vulcan robots have successfully completed pilot testing and are ready to enter the Beta testing phase. The initial pilot program deployed six Vulcan Stow robots at a fulfillment center in Washington State, while the Beta test will expand to thirty robots. Additionally, there will be a larger scale deployment in Germany, where Vulcan Stow and Vulcan Pick will operate in coordination.

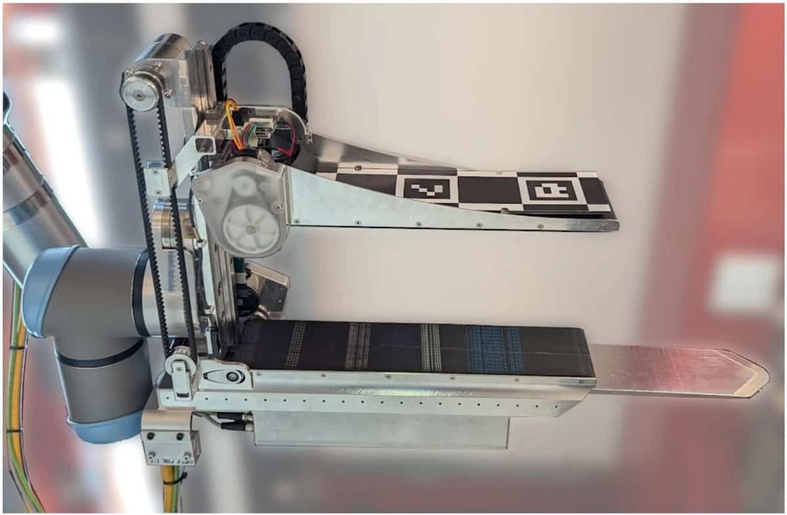

The greatest innovation of the Vulcan robot lies in its end-effector equipped with six-axis force and torque sensors, capable of measuring contact forces in all directions. This sets it apart from the robotic arms currently used in Amazon's logistics centers. Traditional robots can only pick items from conveyor belts or open boxes and must avoid making contact with other objects.

Experts in applied sciences at Amazon Robotics explain that traditional industrial automation has been designed since the 1990s to prevent contact, with robots solely relying on visual and joint information for operation. What sets Vulcan apart is its unique integration of tactile and visual senses, enhancing the operational flexibility of robots.

Taking Pick up a coin. as an example, the Vulcan robot simulates human tactile movements by first making contact with a surface and then gliding along it to locate the target item. This is at the very heart of its technology.

The Vulcan robot is designed with a fabric storage rack featuring small compartments, allowing items to be placed randomly and secured with elastic bands, making it nearly impossible to retrieve or place items without coming into contact with others. Both models of the robot are equipped with a second arm specifically for handling the elastic bands.

The Vulcan Stow system constructs precise 3D models of storage racks and their contents using three pairs of stereoscopic cameras, employing multiple deep learning models for image segmentation to achieve flexible item handling. The team utilizes generative AI to simulate images, training imaging algorithms to overcome the impact of elastic bands on imaging.

During the pickup operation, the system first assesses the feasibility of retrieving the target item. If there are too many obstructing items, manual intervention is required. The Vulcan robot employs structured light technology to measure depth and utilizes an enhanced neural network model to categorize items, enabling the identification of target items without the need for barcode scanning.

This innovation signifies a paradigm shift in robotic operations, evolving from merely moving in free space to effectively handling various items, including locating objects in densely packed areas. The Vulcan robot focuses on managing the upper and lower levels of storage racks, while human staff take care of the middle layers and special items. This collaborative model not only enhances efficiency but also reduces safety risks for employees.

With the continuous growth of e-commerce demand, this innovative technology will help Amazon and other logistics companies meet the increasing order demands while maintaining efficiency and accuracy. In logistics hubs like Hong Kong, the application of such technology will further enhance competitiveness.